- Home

- Product

- Glass Cutting Machine

- CNC 4228 Automatic Glass Cutting Systems(loading,cutting and breaking)

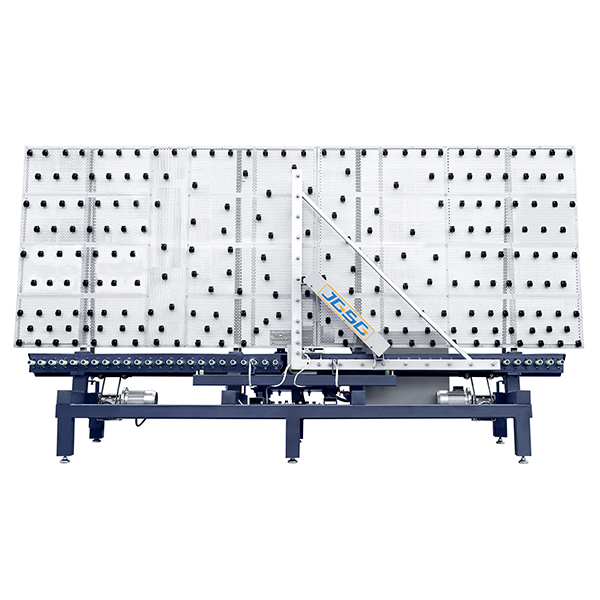

CNC 4228 Automatic Glass Cutting Systems(loading,cutting and breaking)

- This set of equipment is the latest development , which is including loading, taking glass, straight cutting, shape cutting, air flotation, breaking,

- automatically move and walk (around), remote control. It is currently the most advanced automatic glass cutting system, instead of the traditional automatic glass cutting line(loading table, cutting machine, breaking table).

PRODUCT Description

Introduction:

This set of equipment is the latest development , which is including loading, taking glass, straight cutting, shape cutting, air flotation, breaking, automatically move and walk (around), remote control. It is currently the most advanced automatic glass cutting system, instead of the traditional automatic glass cutting line(loading table, cutting machine, breaking table).It is significantly reduce the labor intensity of workers, with convenient operation, low investment and benefit advantages, greatly reducing the cost, it is the best choice for small and medium enterprise.

Feature

1.Innovative system is the only one can guarantee perfect uniformity and constant quality of all the machines that are being built and every single parts of machines can be easy to replace if needed, even the felt table surface.

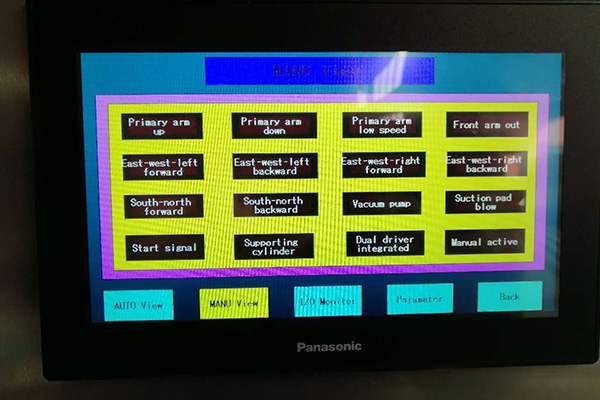

2.Control panel with incorporated independent Computer , software packet with optimization program developed in Multitasking systems, user graphic interface for the managing of the cutting cycle and machine monitoring , hydraulic tilting surface, air cushion, ventilator for the movement of the sheet on the surface

3.Famous imported Electrical components or reliable domestic brands to make high cutting precision and stability, can meet all kinds of shapes of glass cutting.

4.Automatic oil injection and automatic constant pressure regulation functions, effective way to ensure the stability of the cutting and cutting effect. Simple, easy to manage, no special requirements for operators, easy training to start, unskilled workers will be able to operate it too.

5.Safety of the glass presence:

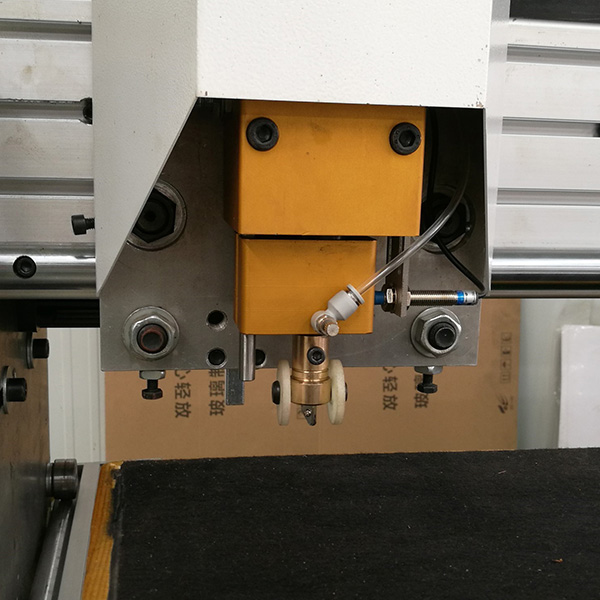

Automatic sensor is placed on the cutting head, to stop the machine in case of lack of glass sheets

6.imported cutter wheels and setting tool.stable voltage power supply,English cutting software, instruction,AUTOCAD Designed graph and figure,all cutting are fully CNC Control

Working process

1) Work flow: After starting the inputting machine, arms automatically suck glass from the shelf. Under sensor controlled, glass automatically find glass edge in the X and Y directions. After moving glass sheets to designated location, transport glass to the automatic cutting table.Cutter will move to coordinate origin, and automatically start to cut according to the preinstall graph.

The operator can edit the glass size for cutting with computer. The computer can optimize the cutting size, and give out the data for processing.

Technical Parameters:

1. The cutting thickness: 2-19mm

2. The cutting accuracy: Parallelism:≤±0.15mm/m

3. The cutting speed: 150m/minute(can be adjustable)

4. The outline size:4600*4200*900mm;

5. The max cutting size:420*2800mm

6. Transmission system: The X、Y、Z Axis are equipped with reliable motor.

7. The cutter block: It adopt pneumatic and spring at the same time. the cutter holder can rotate by 360°degree, and cut the glass up and down.(It can cut any shape)

8. The oiling supply method: Auto oiling.

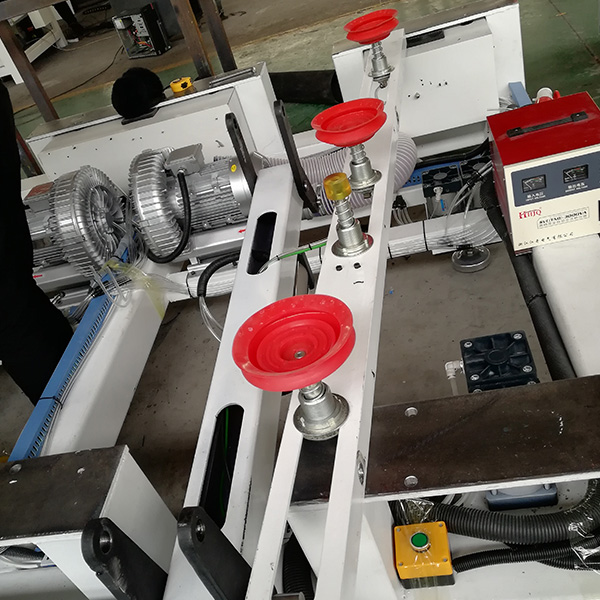

9.The transportation device: It adopt Flotation device which makes it convenient to move the sheet glass.

Mechanical

1. The tabletop: The smoothness≤±0.2mm/m

2. Rack/Guides: Imported from Japan and switzerland.

3. Turret: It use the pneumatic pressure and the spring pressure at the same time to make the cutting best.

Electrical

1. It’s operated directly by pc and adopt Microsoft Windows.

2. Voltage: 380v/50Hz.

Notice:

1. It can cut the glass of various thickness and shapes.

2. The seller should supply the services of installation, commissioning and training(in china).

3. Two years guarantee(Not including the artificial damage), long maintenance.

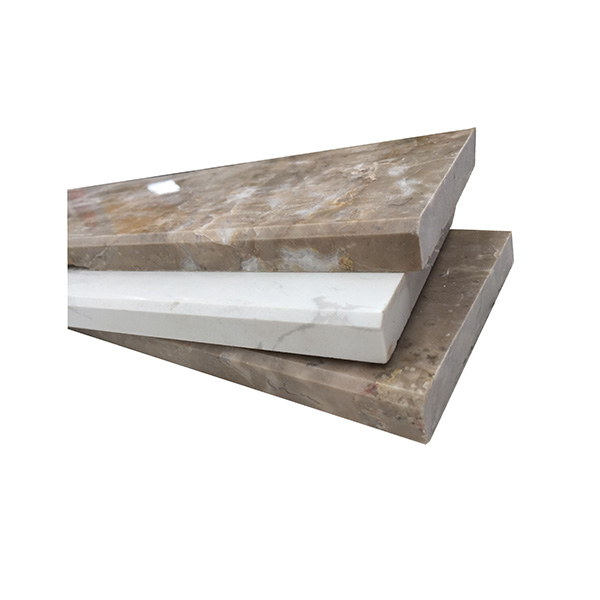

Related Products

CONTACT US

Foshan Shunde Jugang Shengong Glass Machinery Co., Ltd7

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us