How is the stone polished

- By:

- Date:2020/08/12

Stone polishing is an important process for stone conservation. Some stones can be polished directly, and polishing is mainly to increase the brightness of the stone surface.

Stone polishing is generally carried out according to the procedure of rough grinding → semi-fine grinding → fine grinding → fine grinding → polishing, and some of the rough grinding steps can be omitted, mainly depending on whether the surface of the original stone has undergone preliminary treatment.

①Coarse grinding: the grinding disc is required to take a deep knife, the grinding efficiency is high, the grinding pattern is coarse, and the ground surface is rough. It mainly removes the saw blade marks left by the stone in the previous process and the smoothness of the stone , The modeling surface is ground in place;

②Semi-fine grinding: remove the traces of rough grinding, form new finer lines, and make the stone surface smooth and smooth;

③Fine grinding: The pattern, particles and color of the stone surface after fine grinding have been clearly displayed, the surface is fine and smooth, and there is a weak gloss;

④Fine grinding: The surface of the stone after the precision grinding has no traces of naked eyes. The surface is getting smoother, and the gloss can reach up to 55 degrees or more;

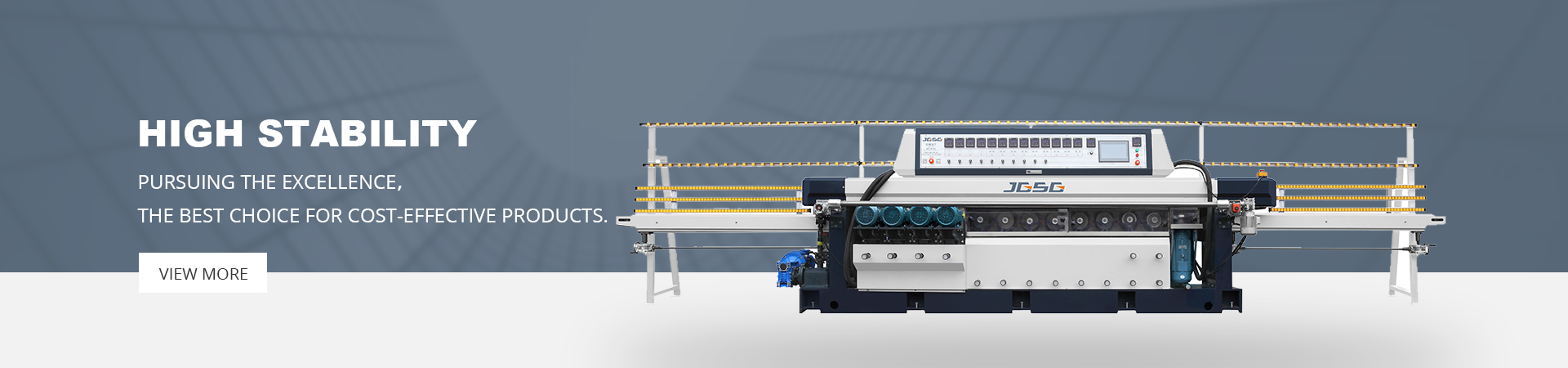

⑤ Polishing: Use a stone polishing machine marble cnc cutting and polishing machine for sale to grinding the stone from coarse to fine stone from No. 50 to No. 3000 to make the ground bright and smooth as new. The polished stone surface is as bright as a mirror, and its gloss can reach over 85 degrees. According to different types of stone, different polishing processes are used.

Finally, I want to say that a very popular and hot selling machine can solve all the above processes efficiently. It is marble cnc cutting and polishing machine for sale . Not only can the polishing effect be achieved at one time, but also the edge shape, round edge and all kinds of edges can be processed easily, and the shape and polishing can be completed in one time, and the fastest work efficiency per minute can work 3m/min. Of course the marble cnc cutting and polishing machine for sale can be customized according to different customers and different needs, customize the shape you want, the effect you want

There is such a marble cnc cutting and polishing machine for sale , are you sure you are not interested ?

CONTACT US

Foshan Shunde Jugang Shengong Glass Machinery Co., Ltd7

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us