Stone Edging Machine

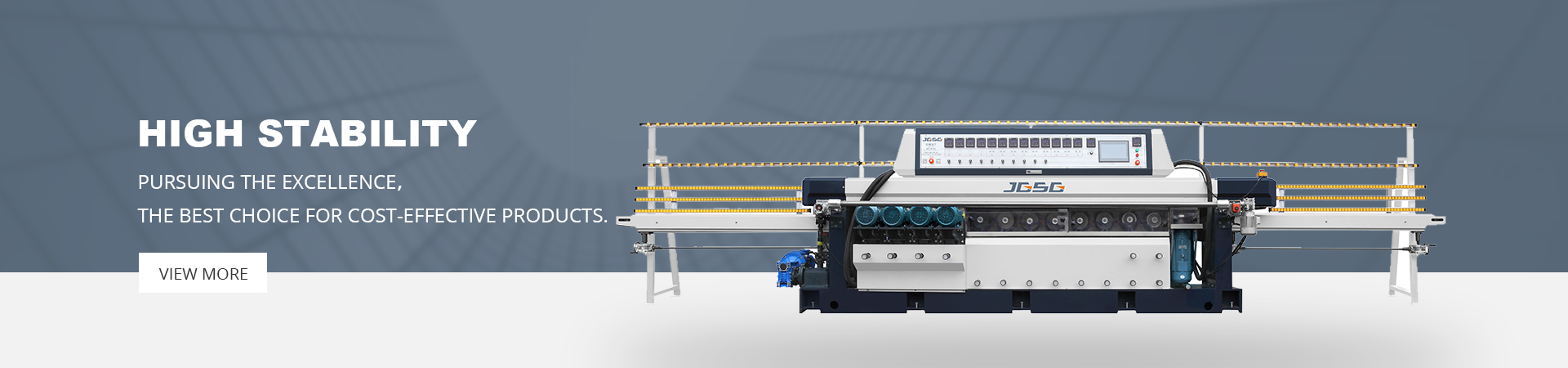

JGSG is a professional Vertical Straight Glass Edging Machine Wholesale and Slate Stone Edging Machines Manufacturers engaged in the research, production and sales of rock slab and stone edging machine. Also a integrates glass edging machine equipment scientific research, production and sales.

High quality, high cost performance, and strive to be an excellent Slate Stone Edging Machines Manufacturers of rock slab and stone machinery is the common goal of the JGSG team. Stone edging machine has the advantages of advanced structure, high precision, easy operation. Glass edging machine is widely used in the processing of various flat glass products, such as cabinets, doors and windows, furniture and so on.

JGSG as a slate stone edging machines manufacturers, our product are sold well both at home and abroad, and are favored by people from all walks of life. Stone edging machine is used for grinding and polishing of marble and granite. Can also be used for grinding and polishing of step stones. The characteristics of the glass edging machine are three: one is that it has a single purpose and can only grind various straight edges; the second is that it can be ground continuously and has a high production efficiency; the third is that it can grind flat glass with a large size.

-

-

-

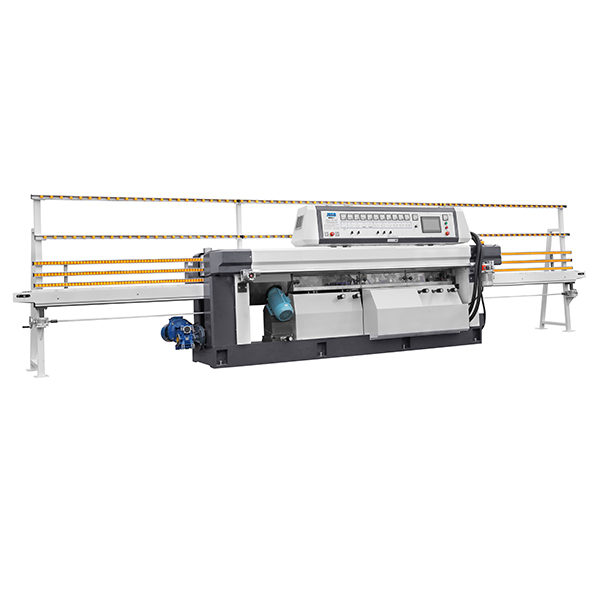

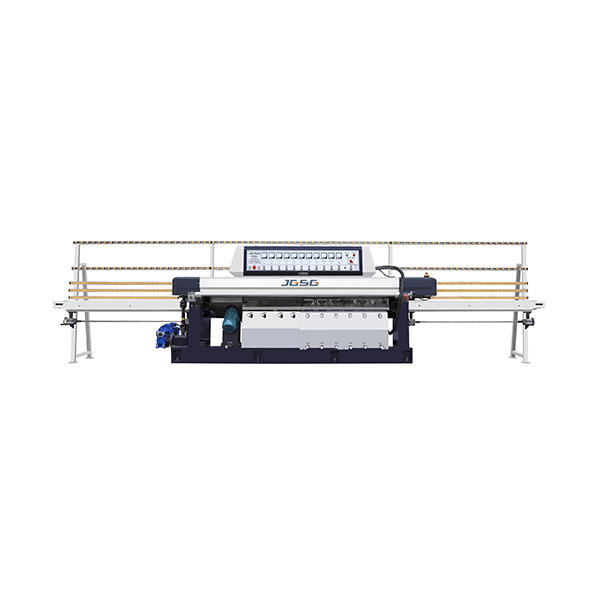

Automatic Rock Plate/Stone Edge Machine JGZM10-45°A

Multifunctional rock slab processing machine, capable of processing 45°.

Beveled edges and seamless splicing can also be grooved on the surface. It is suitable for linear processing of various rock slabs, such as dining tables, cabinets, kitchens, bathrooms, floors, etc.

This machine is suitable for grinding 45° edging of different sizes and thicknesses and straight-edged plane processing can be done through rough machining, fine edging and polishing at one time. After edging, it is close to flatness. The stone matrix adopts frequency conversion speed feed, which can adjust the thickness of different processes, and can be adjusted according to the digital display table of the front beam. The machine has advanced structure, high precision, convenient operation and continuous thickness processing.

-

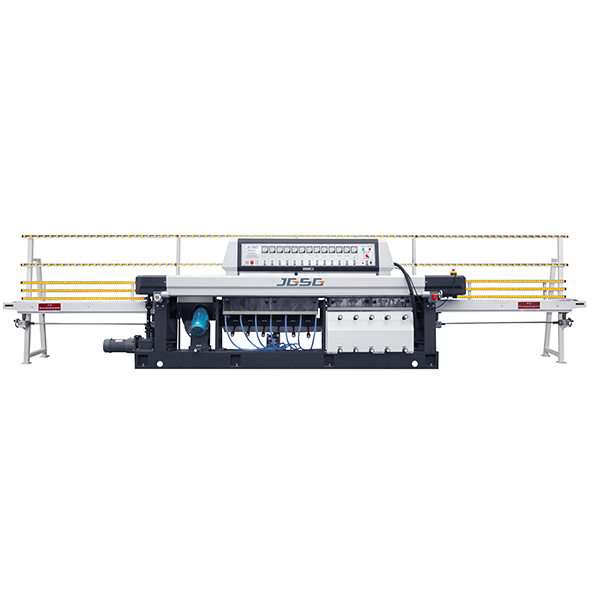

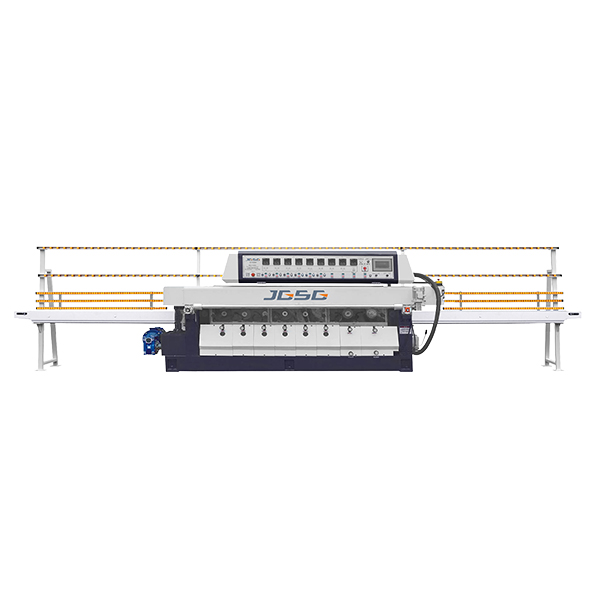

Automatic Rock Slab Stone Straight Machine JGZ10-45°

This machine frequency conversion speed regulation feed material is suitable for the flat stone material of different size and thickness the straight side and the bottom side and the 45 degree Angle, kicks the foot line to grind, the coarse fine grinding polishing completes once. The plane after polishing is close to the degree of brightness of stone matrix, when adjusting different processing thickness (refer to the digital display table on the front beam for adjustment), it has the advantages of advanced structure, high accuracy, convenient operation, continuous processing of the same thickness, and so on. It is a necessary processing equipment for deep processing of stone.

-

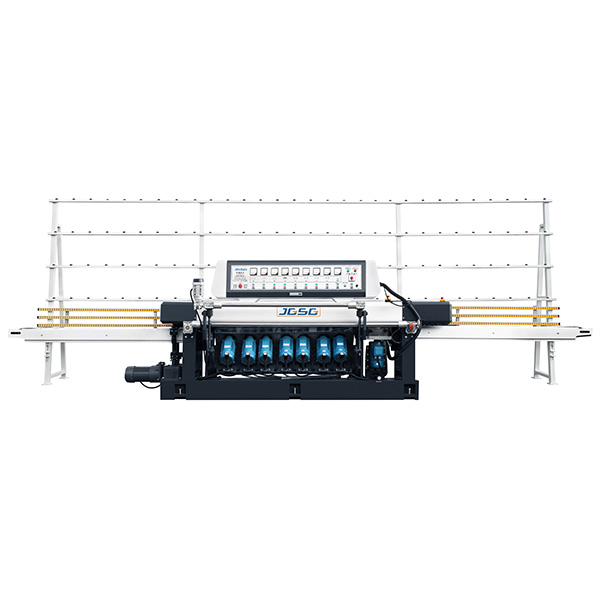

Automatic Rock Slab Stone Round Machine JGYM08

The frequency conversion speed feed of the machine is suitable for straight round edges, duckbill edges and shaped edges of flat stone of different sizes and thicknesses. The rough grinding is completed once. The polished surface is close to the smoothness of the stone matrix. When adjusting the thickness of different processing, (refer to the digital display on the front beam for adjustment), it has the advantages of advanced structure, high precision, convenient operation, continuous processing of the same thickness, etc. The necessary processing equipment for deep processing of stone.

-

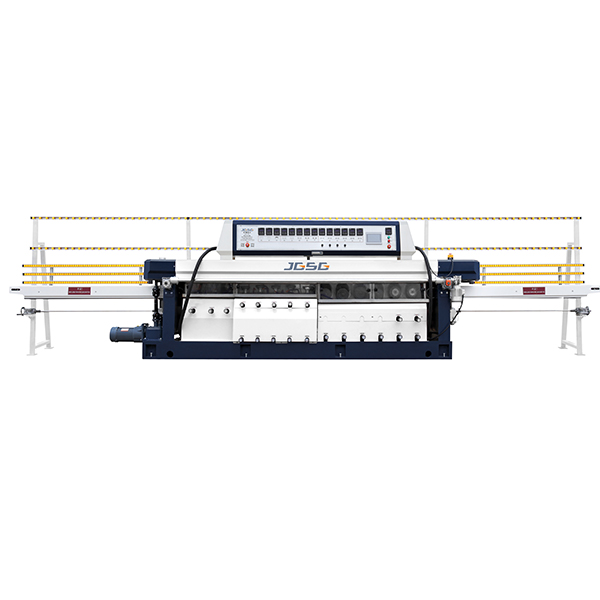

Automatic Rock Stone Edge Machine JGZM11P-45°

The machine is suitable for grinding straight stone and 45°edging stones with different sizes and thickness.The 45°oblique plane and straight side plane processing can be finished by rough,fine edging and polishing at once.After polishing,it is close to the smoothness of the stone matrix,Using variable frequency speed feed,it can adjusting the thickness of different processing,it can be adjusted according to the digital display table on the front beam.This machine has the advantages of advanced structure,high accuracy,convenient operation and continuous thickness machining.It is a necessary equipment for deep processing of stones.

-

Automatic Rock Slab Stone Straight Line Machine JGZM12-45°

The machine can be equipped with different grinding wheels,grinding the straight round edge of the flat-skin material,straight-line duck-bulled edge and straight line shaped edge coarse grinding ,fine grinding ,and polishing are completed at one time,and the effect after processing is close to that of the original stone sheet,Frequency control feed,can be arbitrary conversion processing speed.

-

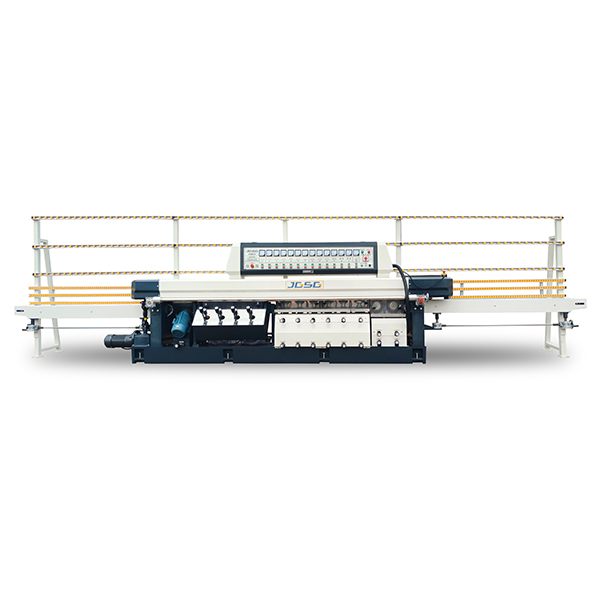

JGS10-45°

The machine is suitable for grinding straight stone and 45°edging stones with different sizes and thickness.The 45°oblique plane and straight side plane processing can be finished by rough,fine edging and polishing at once.After polishing,it is close to the smoothness of the stone matrix,Using variable frequency speed feed,it can adjusting the thickness of different processing,it can be adjusted according to the digital display table on the front beam.This machine has the advantages of advanced structure,high accuracy,convenient operation and continuous thickness machining.It is a necessary equipment for deep processing of stones.

-

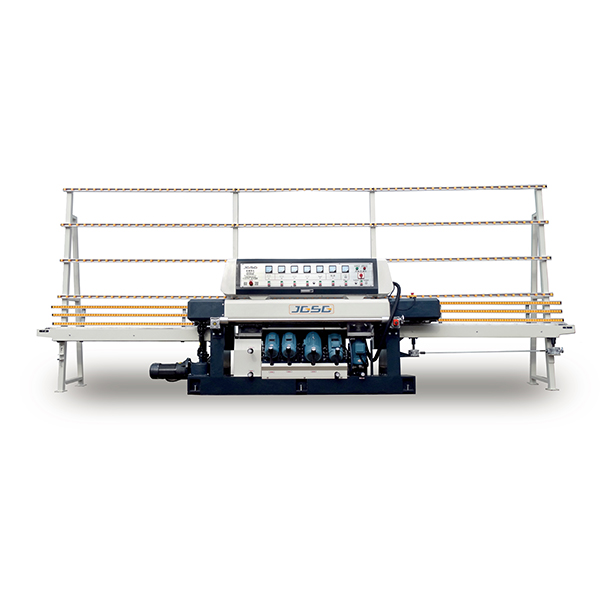

JGS09-45°

The machine is suitable for grinding straight stone and 45°edging stones with different sizes and thickness.The 45°oblique plane and straight side plane processing can be finished by rough,fine edging and polishing at once.After polishing,it is close to the smoothness of the stone matrix,Using variable frequency speed feed,it can adjusting the thickness of different processing,it can be adjusted according to the digital display table on the front beam.This machine has the advantages of advanced structure,high accuracy,convenient operation and continuous thickness machining.It is a necessary equipment for deep processing of stones.

-

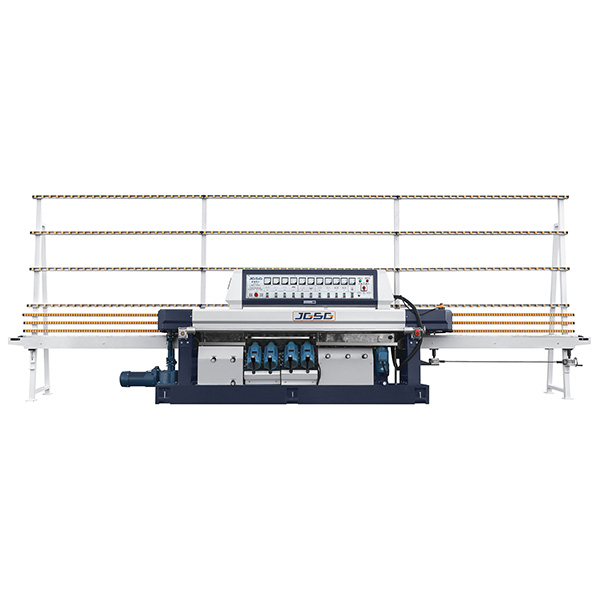

Automatic Rock/Plate Stone Straight Machine JGS08-45°

The machine is suitable for grinding straight stone and 45°edging stones with different sizes and thickness.The 45°oblique plane and straight side plane processing can be finished by rough,fine edging and polishing at once.After polishing,it is close to the smoothness of the stone matrix,Using variable frequency speed feed,it can adjusting the thickness of different processing,it can be adjusted according to the digital display table on the front beam.This machine has the advantages of advanced structure,high accuracy,convenient operation and continuous thickness machining.It is a necessary equipment for deep processing of stones.

-

Automatic Rock Board Stone Round Machine JGS-14P

The machine can be equipped with different grinding wheels,grinding the straight round edge of the flat-skin material,straight-line duck-bulled edge and straight line shaped edge coarse grinding ,fine grinding ,and polishing are completed at one time,and the effect after processing is close to that of the original stone sheet,Frequency control feed,can be arbitrary conversion processing speed.

-

Automatic Rock Board Stone Round Machine JGS-13P

The machine can be equipped with different grinding wheels,grinding the straight round edge of the flat-skin material,straight-line duck-bulled edge and straight line shaped edge coarse grinding ,fine grinding ,and polishing are completed at one time,and the effect after processing is close to that of the original stone sheet,Frequency control feed,can be arbitrary conversion processing speed.

-

Automatic Rock Slab Stone Straight Line Machine JGS13-45°

The machine can be equipped with different grinding wheels,grinding the straight round edge of the flat-skin material,straight-line duck-bulled edge and straight line shaped edge coarse grinding ,fine grinding ,and polishing are completed at one time,and the effect after processing is close to that of the original stone sheet,Frequency control feed,can be arbitrary conversion processing speed.

-

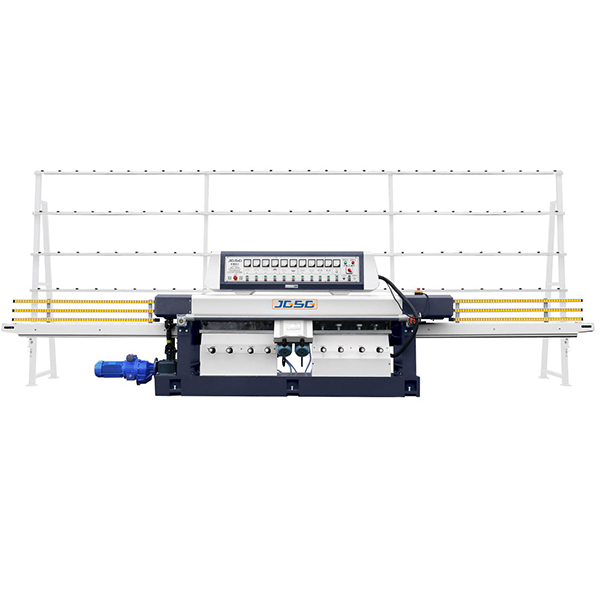

Automatic Stone Edge Machine JGZM11-45°

The machine is suitable for grinding straight stone and 45°edging stones with different sizes and thickness.The 45°oblique plane and straight side plane processing can be finished by rough,fine edging and polishing at once.After polishing,it is close to the smoothness of the stone matrix,Using variable frequency speed feed,it can adjusting the thickness of different processing,it can be adjusted according to the digital display table on the front beam.This machine has the advantages of advanced structure,high accuracy,convenient operation and continuous thickness machining.It is a necessary equipment for deep processing of stones.

-

Automatic Rock Slab Stone Round Machine JGYM08S

JGS08S stone straight edge grinding machine adopts a set of artificial intelligence operation control system,Each mechanical action is controlled by a computer - written program.Through the man-machine interface and the operator to set the exchange,and the signal proveded by the automatic detection system,the machine is set up two sets of programs are targeted for real-time operations.They are a granite program and a marble program.when working,just switch the program,you can do automatically stop working of the polishing system when there is stone,automatically stop working when there is no stone,and six polishing wheels can automatically compensate according to the degree of abrasive wear,effectively guarantee continuous and consistent polishing effect.Avoid the laborious workload caused by manual compensation until the polishing wheel is used up for replacement,and then replace it with a key wheel replacement function.The humanized function and intelligent operation are the characteristics of this device.

CONTACT US

Foshan Shunde Jugang Shengong Glass Machinery Co., Ltd7

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us