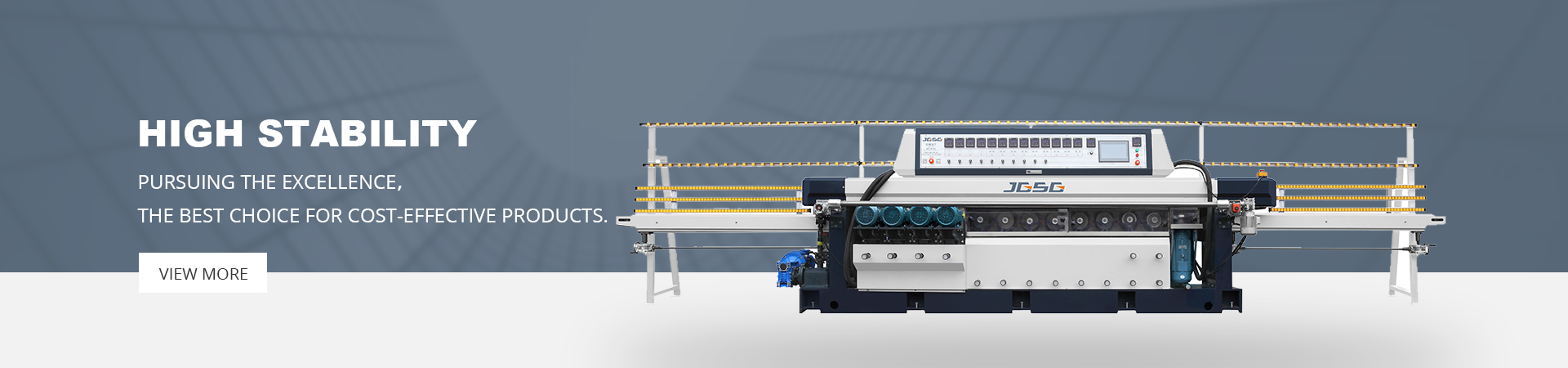

Marble edging machine

- By:

- Date:2020/10/10

There are also many machines used in stone processing. With the assistance of these marble edging machines, it is possible to better process stone with good craftsmanship. Now I will introduce the installation process of the marble edging machine.

1. Preparation

Early stage: enough equipment space, corresponding power of three-phase power (zero line is required), corresponding specifications of the empty cable, circulation of sedimentation tank, water pump and water pipe, wheel, SLATE, operators.

Later stage: corresponding tonnage forklift or small hydraulic truck jack, level or horizontal pipe, installation tools, various specifications of the floor and gasket.

2.Check the

First of all, check whether all parts of the equipment are in good condition and the number of parts is correct. If the equipment is lost or damaged during transportation, communicate with the company and customers in time and deal with it at the first time. If there is any problem with the parts, contact the company for replacement or replacement.

3. The installation

Placement: The placement position of the marble edging machine shall be reserved at the end of the material inlet and outlet for no less than the length of the line frame. If the machining side has special requirements, such as long lines, the size of the line shall be taken as a reference. The rear side of the equipment shall have a space of no less than 1 meter, which is convenient for technicians to maintain and process the line.

Leveling: The leveling of the edging machine shall be based on the conveying belt, measuring the four edges of the belt, but it shall be kept within.

Electricity connection: If the customer does not arrange electrical wiring, the installer can assist the customer to connect the line from the main switch to the equipment switch. The line machine must distinguish three groups of live and neutral wires. If the cable ends, press and wrap the wires tightly. Insulating tape and wiring terminals must be tightened.

Receiving water: If the customer does not arrange for a plumber to take over, the installer can assist the customer to connect the circulating water pump to the water pipe of the equipment.

Refueling: Fill the edging machine with lubricating oil, and cover the external bearings of the equipment with butter.

4. Debug

Turn on the power, if the phase sequence protector is not lit, it means that the three-phase line is connected incorrectly. You can switch the two phases at will. Click on the screen and run the conveyor belt to see if the steering is correct. Turn on the motor spindles to see if the steering is correct and the spindle threads The positive and negative are correct, whether the lifting is normal, whether the grinding wheel is smooth, check the limit, check whether the reference numbers in the touch screen are correct, whether the ammeter is accurate, whether the wheels are in and out smoothly, and whether the automatic is sensitive.

CONTACT US

Foshan Shunde Jugang Shengong Glass Machinery Co., Ltd7

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us