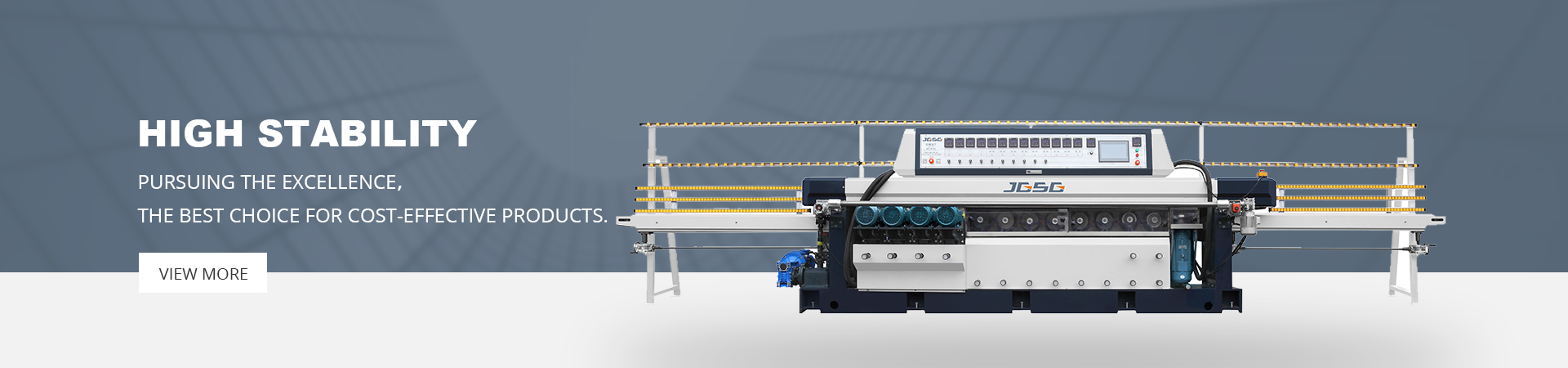

Glass chamfering machine

- By:

- Date:2020/12/16

Glass chamfering is a very important step in the glass processing process. It is not only for the beauty of the glass, but also for reducing the damage that the glass may cause to the human body during the use and installation. This requires the use of a glass chamfering machine.

The glass chamfering machine can be applied to the processing of glass products that require chamfering, such as bathroom glass, furniture glass, and architectural glass. It is a common equipment among glass deep processing enterprises. However, in the past, the accuracy of glass chamfering machines was poor, and The work efficiency is low, and it is increasingly unable to meet the needs of glass deep processing enterprises.

Especially in the increasingly fierce market competition, only new technologies, new equipment and new processes can break the homogenization situation, increase enterprise productivity, reduce production costs, and create greater profit margins for enterprises.

Operators should pay attention when using the glass chamfering machine:

1. The operator should be familiar with the performance of the glass chamfering machine and the method of blade replacement.

2. The operator should wear protective gear, goggles and cuffs.

3. Lubricate the glass chamfering machine with No. 10-20 oil every day.

4. In order to obtain the ideal chamfer, you need to select the appropriate chamfer size and have the ideal feed speed (larger feed speed = 1.1 m/min). If the chamfer size is too large and the feed speed is too fast, it is easy to cause vibration, tool collapse and shutdown.

5. Use the glass chamfering machine for the first cutting, do not allow rapid depth, but must feed slowly, until the blade cuts into the set depth before cutting at normal speed.

6. If the machine fails during operation or the blade is replaced, the air supply must be cut off before maintenance.

7. In case of failure, it is forbidden to disassemble it in an unclean environment, and it should be sent to the repair department for maintenance in time.

8. After the work is finished, it must be lubricated with oil and run for a few seconds to prevent corrosion.

9. When replacing the blade, the Allen wrench should be put in place and the force should be even to prevent damage to the thread.

CONTACT US

Foshan Shunde Jugang Shengong Glass Machinery Co., Ltd7

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us